Kase K6000 full remanufacturering

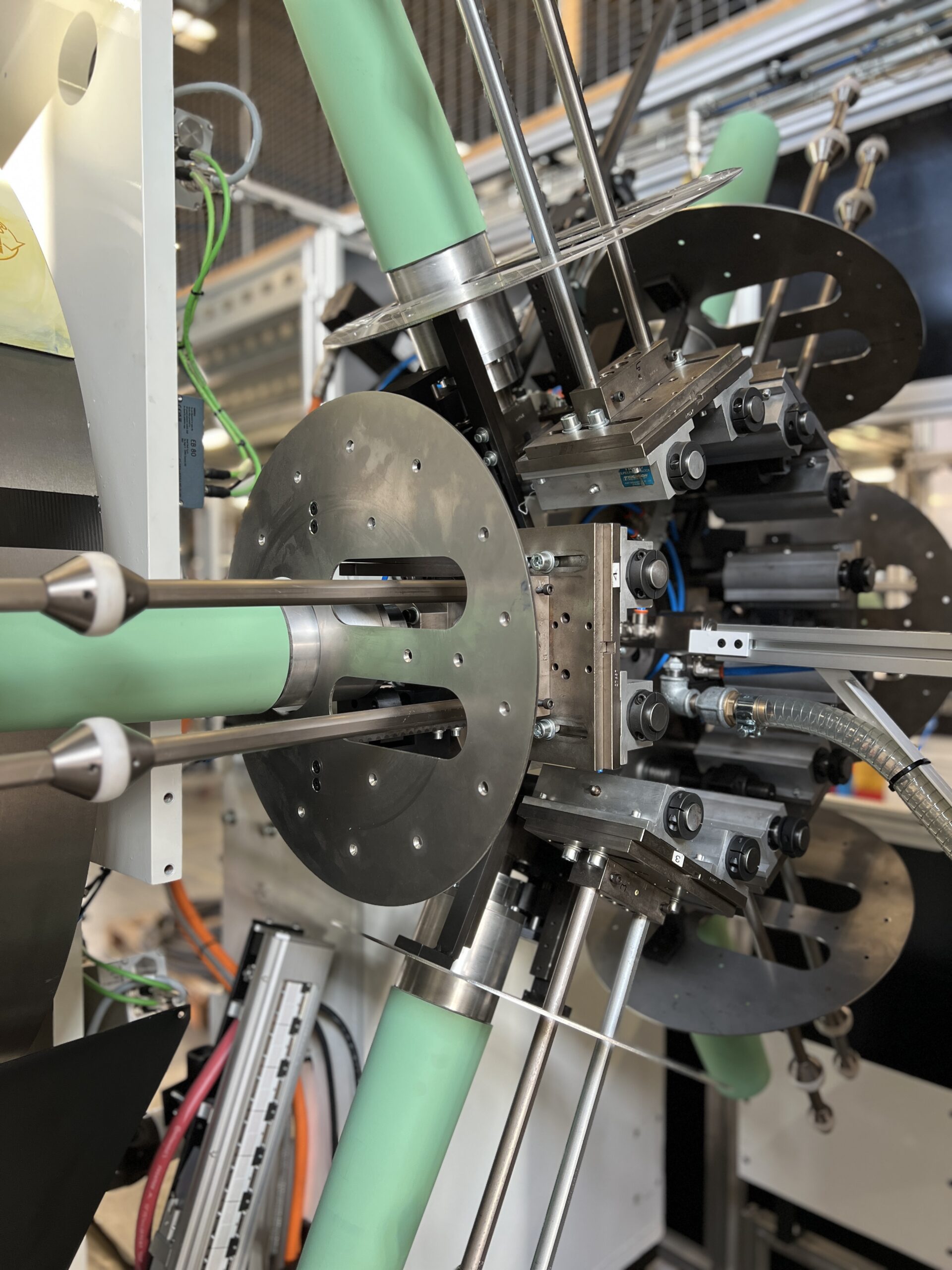

The original pail printing machine was dated 2006 and for round pails. Remanufactured to new condition / upgraded to TORQ-indexing system in 2024/25.

- free positioning indexing system

- adjustable air and gas flow

- pre-orientor

- UV LED curing system

- NEW Siemens PLC

The Brief

We offered the customer a 6 positions indexing system; flexible thanks to a NEW servo driven free positioning indexing system. The expendable mandrels are included.

Pre-treatment system: gas flame. Adjustable air and gas flow to adjust correct flame and treatment

level. Electronic flame igniter. Pivoting adjustable burner. Variable speed mandrel spinner to control rotation speeds. ON/OFF selector for flame treatment on HMI control panel.

Pre-orientor: adds 10-20% to printing speed, depending on container size. Orients the pail before print position. Orientor in printing position will only fine-tune orientation. Adjustable to different pail diameters.

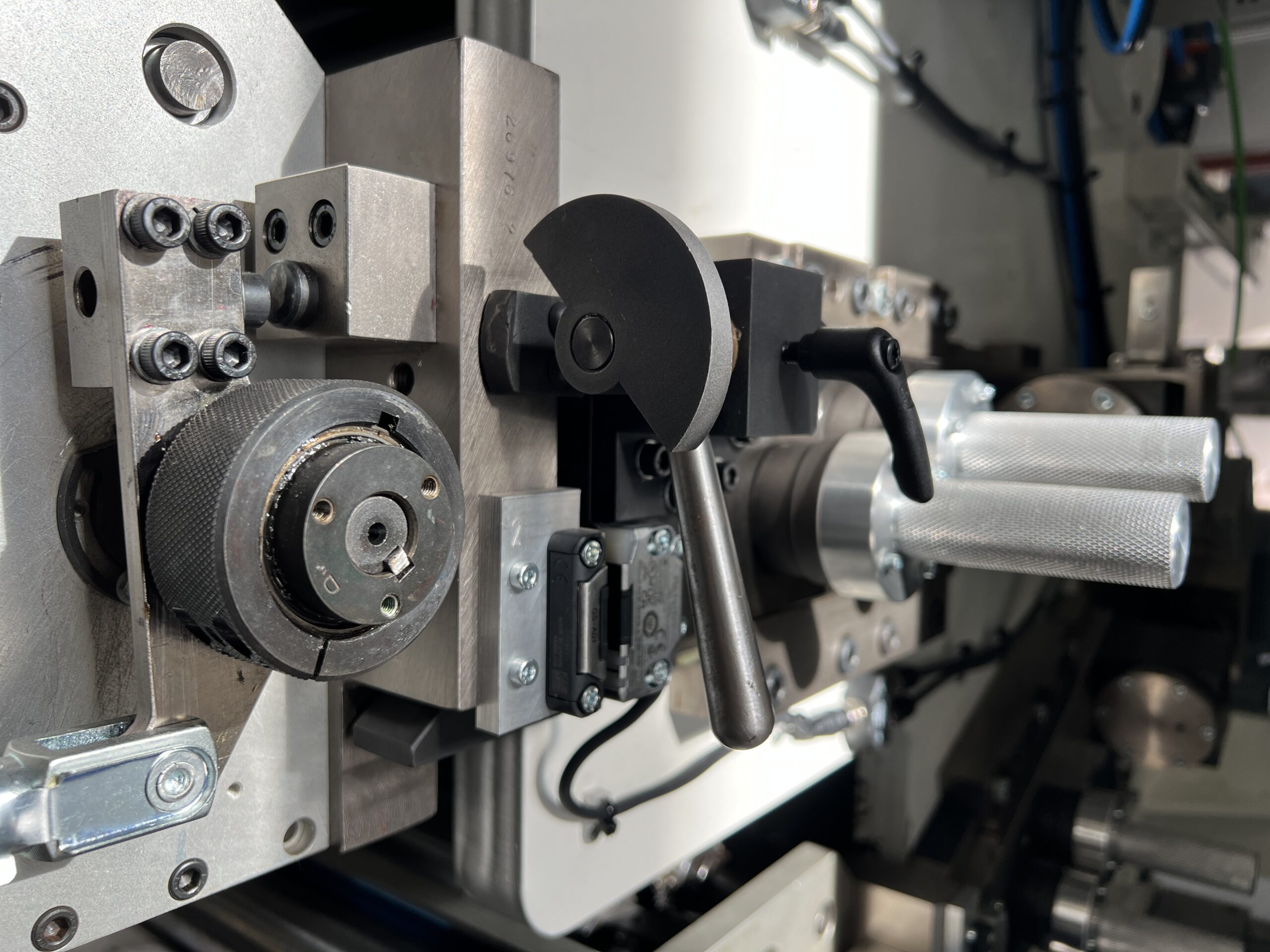

Orientor in print position. Adjustment for print location between ear blocks. Handles different pail diameters. Variable speed mandrel drive.

UV LED curing system (replacing Mercury Vapor curing system). Instant on-off availability. Variable speed mandrel spinning system for controlled rotation in curing position.

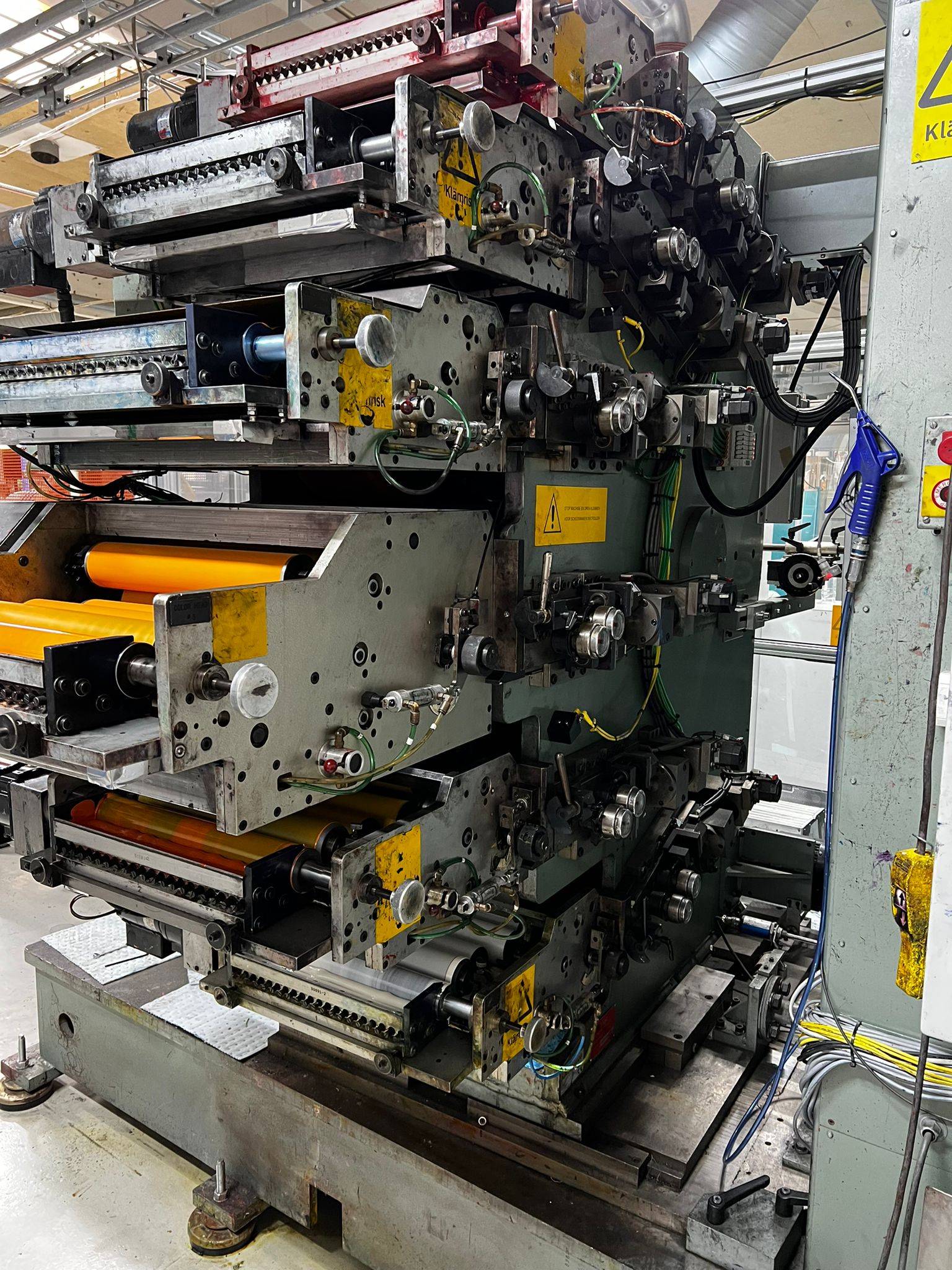

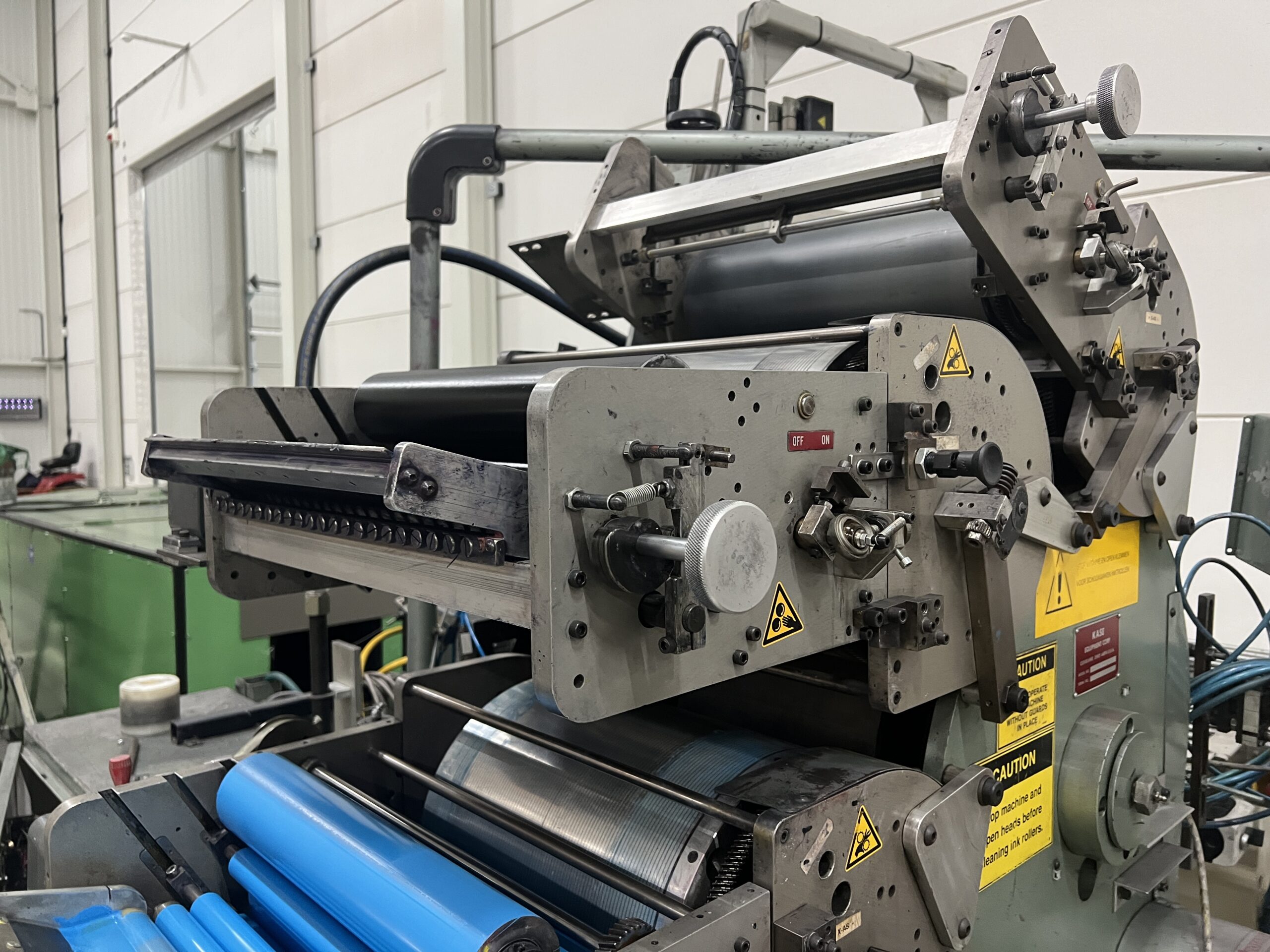

Printing station for 6 colours. One Colourhead with 12 inch form roller, five colourheads with 6 inch form roller.

Magnetic plate cylinders with running register. Hold-on system. Outfeed belt; 250cm long discharge belt. Electrical and pneumatical controls, NEW Siemens PLC. NEW functional HMI control touch panel. Documentation. Full remanufacturing to new condition in our workshop. Delivered according to UL regulations; safety category 3. Factory acceptance test in our workshop.

- Max. printing length 940 mm

- Max. printing height 355 mm

- Min. printing diameter 100 mm

- Max. product height 406 mm

- Max. product rim diameter 406 mm